Within the scope of this work package, the purification of the gas mixture generated thus far is being investigated, with a focus on the selective material storage and release of hydrogen from the generated mixed gas stream.

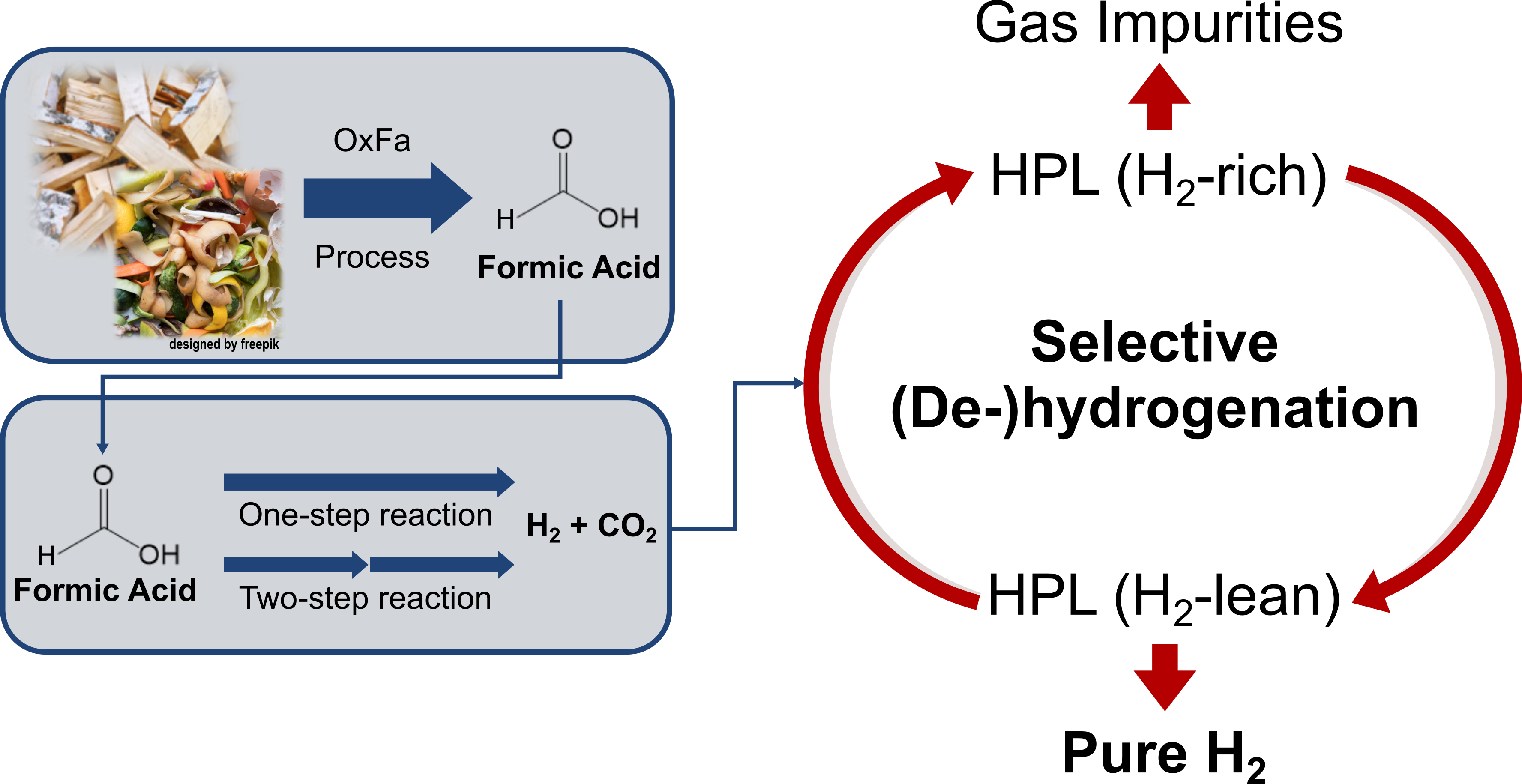

The biomass-derived formic acid obtained from the OxFA process is initially converted into mixtures consisting of H2 and varying proportions of CO2 or CO in a pre-treatment step. Since most common fuel cells are sensitive to CO poisoning and exhibit a decrease in performance or even a complete loss of performance when the hydrogen stream is diluted, a pre-treatment of the gas stream with selective separation of hydrogen from the product stream is essential.

As part of the BMFTR project FAIR-H2, hydrogen purification is carried out using selective hydrogenation and subsequent dehydrogenation of a hydrogen purification liquid (HPL). Suitable catalysts for the hydrogenation step are to be identified, which do not show significant activity drops in the presence of gas impurities and are long-term stable under the existing reaction conditions. Phosphorus-modified supported Pd catalysts, which have already demonstrated stable conversion in similar applications, are being investigated. After identifying suitable catalysts and optimal operating conditions, which represent a compromise between the energy used (pressure, temperature) and high (de)hydrogenation rates, the coupling of dehydrogenation and hydrogenation, the implementation and testing of the technical cyclic operation unit will be carried out.