Selective catalytic oxidation of biogenic resources to organic acids using multiphasic reaction system including in-situ product isolation (SelkatOx)

Biomass can be rated as another important energy resource. The latter is defined as all substance of organic origin, which contains carbon – for example cellulose or polysaccharides from plants. While wind- and solar energy fluctuate depending on the weather, biomass is seasonal available and represents as an energy resource the only regenerative carbon-source. To harness the naturally grown biomass effectively the conversion into easier to handle substances is intended. In this way the energy density is increased and the transport becomes more efficient. Lignocellulosic biomass appears to be suitable as a renewable resource. It is the main component of plant material and consists mainly of cellulose, hemicellulose and lignin.

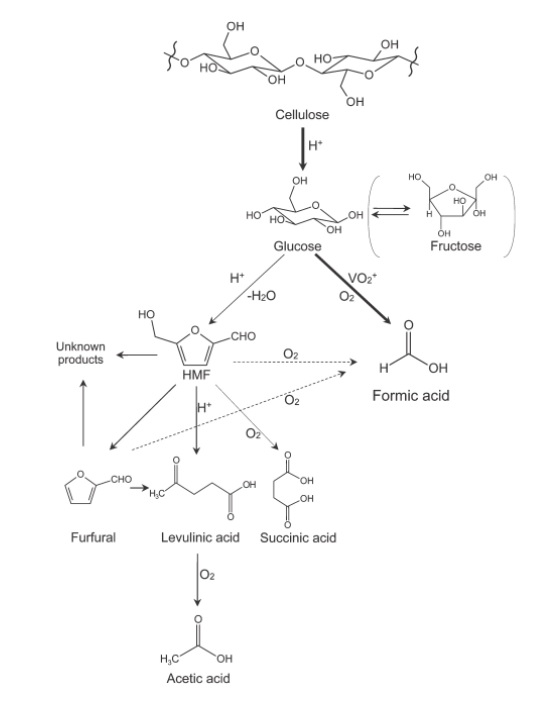

By using polyoxometalate catalysts (POMs) which are part of intensive research at the CRT for a considerable time, desired products like acetic or formic acid could be detected after the oxidation of lignocellulosic biomass. The objective of this research is producing further technical relevant organic acids by applying defined reaction conditions. The property of the catalyst to support different routes of degradation depending on the reaction conditions is considered as very important.

|

|

|

http://www.stromneu.de/biomasse.php

M. Niu, Y. Hou, S. Ren, W. Wang, Q. Zheng und W. Wu, „The relationship between oxidation and hydrolysis in the conversion of cellulose in NaVO3 – H2SO4 aqueous solution with O2“, Green Chemistry, 2015, 17, 335-342

This project harbors great potential since also the hardly accessible lignin can be converted by choosing suitable catalysts and process conditions in contrary to traditional wood refining processes. Previous experiments showed that there is a relation between reaction temperature and acid yield. So it became apparent that increasing temperatures lead to higher acids. The objective is now to understand the complex, simultaneous running processes during the catalytic conversion and to optimize the yield of the desired valuable product. With our research we contribute to an enhanced production of platform chemicals out of renewable resources to enable a sustainable alternative to fossil carbon sources.

This project is financially supported by the Vector-Stiftung under the funding code 2016-033 for a period of about 2 years.